Sawgrass Substrates

The Challenge

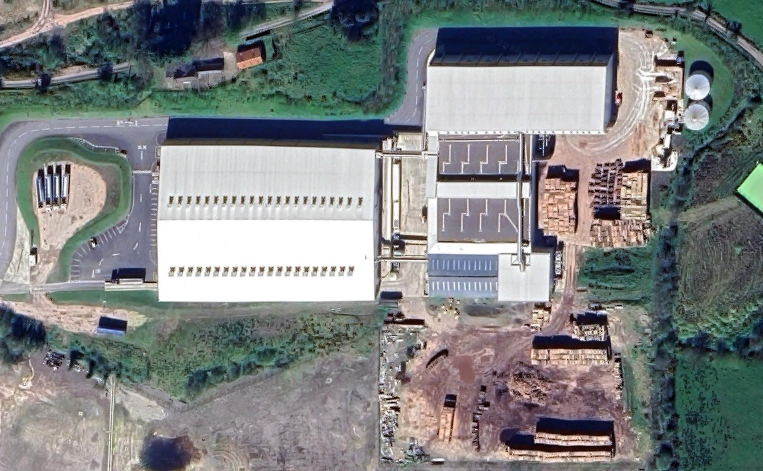

Sawgrass Substrates wanted to increase control over their supply chain by producing compost in-house for their mushroom cultivation. The Ballygawley site, however, presented several technical challenges that required a creative approach.

Specific challenges:

- Topography: Significant elevation differences required earthworks

- Space limitations: Available plot allowed only a limited building length

- Indoor requirement: The entire composting facility had to be installed indoors

- Logistical needs: Direct loading from tunnels onto trucks without intermediate storage

- Material logistics: Optimal balance between locally available and imported components

The GTL Approach

GTL’s solution-oriented approach made the difference. Where others proposed standard solutions, we designed a fully customized system.

Innovative design choices:

- Custom filling cassette: A narrower fill-entrance required a cassette with 5 belts instead of the standard 4, enabling direct loading

- Site-optimized layout: Minimal earthworks using natural elevation differences

- Future-proof planning: Expansion capability incorporated despite space limitations

- Local integration: Careful selection of materials based on local availability

The Project Timeline

Timeline: 2014 – 2019 (5 years from first contact to start-up)

- 2014: Initial contact and concept development

- 2014–2016: Pre-project phase including permitting procedures

- 2017–2019: Engineering and construction

- Early Q2 2019: Successful start-up

The longer pre-project phase was mainly due to complex permitting procedures, in which we fully supported the client.

Immediate results

- High-quality compost production from day one

- Full control over quality and timing

- Significant cost savings through in-house production

Partnership in Practice

GTL’s involvement extended beyond delivery and installation. We ensured a seamless transition to independent production:

- Intensive guidance: GTL specialists on-site for months during start-up

- Knowledge transfer: Extensive training of the local team

- Continuous optimization: Weekly contact for process improvement

From Junior Project Leader to Expert: Learning on the Job

At GTL, we believe the best way to learn is by doing. Our junior project leader, Jip, gained hands-on experience during the construction phase at Sawgrass in Northern Ireland, working as both technician and foreman.

By working on-site for several months, he gained insight into the technical challenges and project execution – from foundations to fine-tuning. Back in the Netherlands, Jip could immediately apply his knowledge as a full-fledged project leader for new assignments. This is a prime example of how we develop junior talent by giving them responsibility in challenging projects.

Our Added Value

GTL added value at every stage of the project:

- Concept Phase: Creative solutions for complex spatial challenges

- Engineering: Customized design tailored to local conditions

- Permits: Full process management

- Execution: Professional project implementation, including 200 transports

- Start-up: Intensive guidance to ensure optimal performance

- Aftercare: Ongoing partnership for further optimization