Spawn Applicator

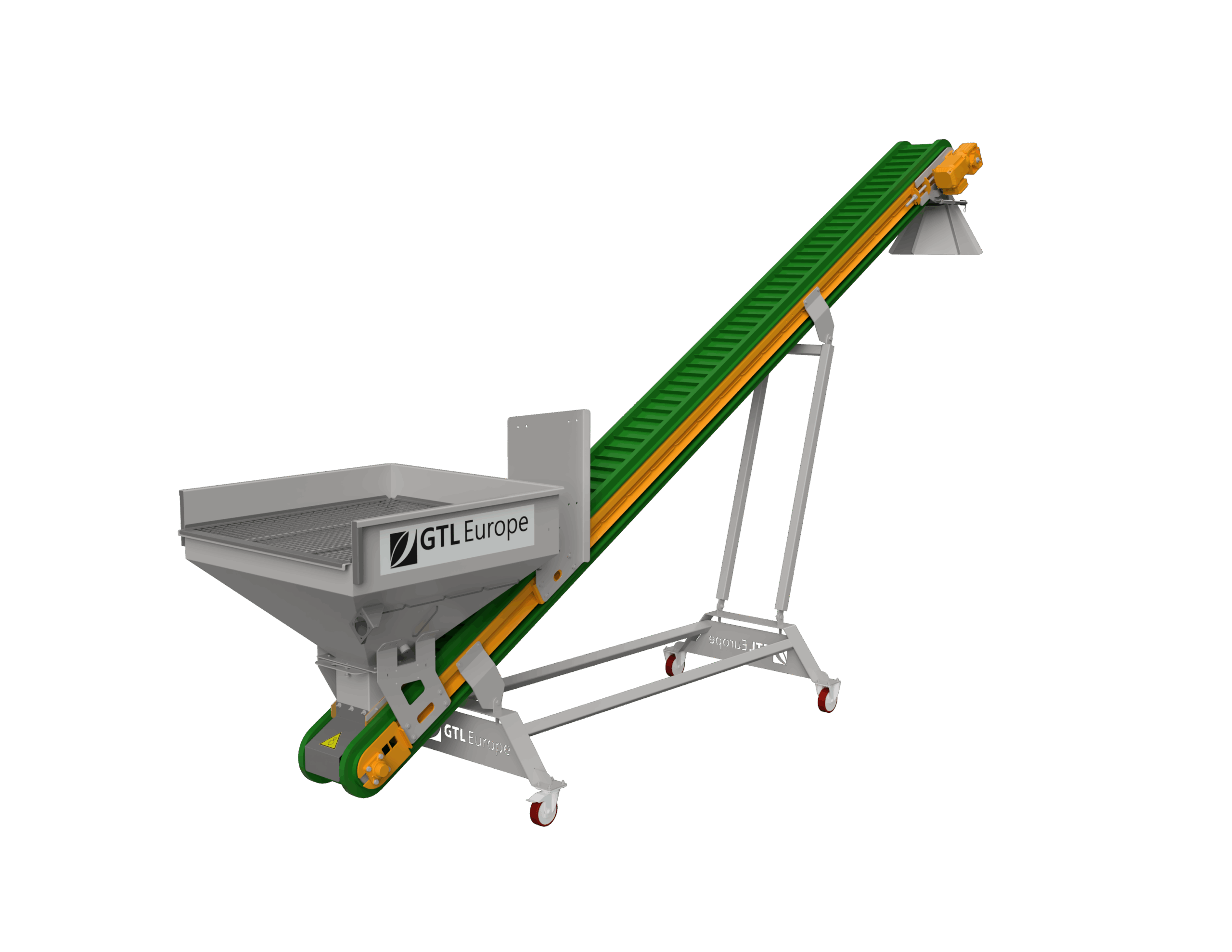

The GTL spawn applicator is designed to evenly add spawn to Phase 2 compost on the conveyor of a tunnel emptying winch. With a mobile frame and dosing hopper, the machine ensures precise and consistent distribution of spawn, contributing to optimal mushroom growth and yield.

Thanks to its flexible design, the spawn applicator can be directly connected to the tunnel emptying winch, integrating seamlessly into the Phase 2/3 compost line. Its robust construction and precise dosing system guarantee reliable performance and reduce manual labor.

FAQ

What does a spawn applicator do?

A spawn applicator adds spawn accurately and evenly to Phase 2 compost for optimal mushroom growth.

How does the spawn applicator work?

Spawn is poured into the hopper, and a dosing mechanism controls the amount released onto the conveyor. The conveyor then distributes the spawn evenly over the compost.

Can it be integrated into existing compost lines?

Yes, it can be connected to the tunnel emptying winch as part of the Phase 2/3 line.

What are the benefits for growers?

-

Accurate and uniform spawn application

-

Reduced manual labor

-

Durable and reliable construction

Is the machine mobile?

Yes, the mobile frame allows the machine to be easily moved within the compost area.

Why choose GTL’s composting machines?

Because GTL designs, manufactures, and installs every system in-house, ensuring reliability and top quality.

Can GTL adapt the machine to my company’s needs?

Yes, every machine is customized to meet the client’s specific requirements and conditions.

What service and support does GTL provide?

We provide installation, training, after-sales, and worldwide service.