Tunnel Emptying Winch

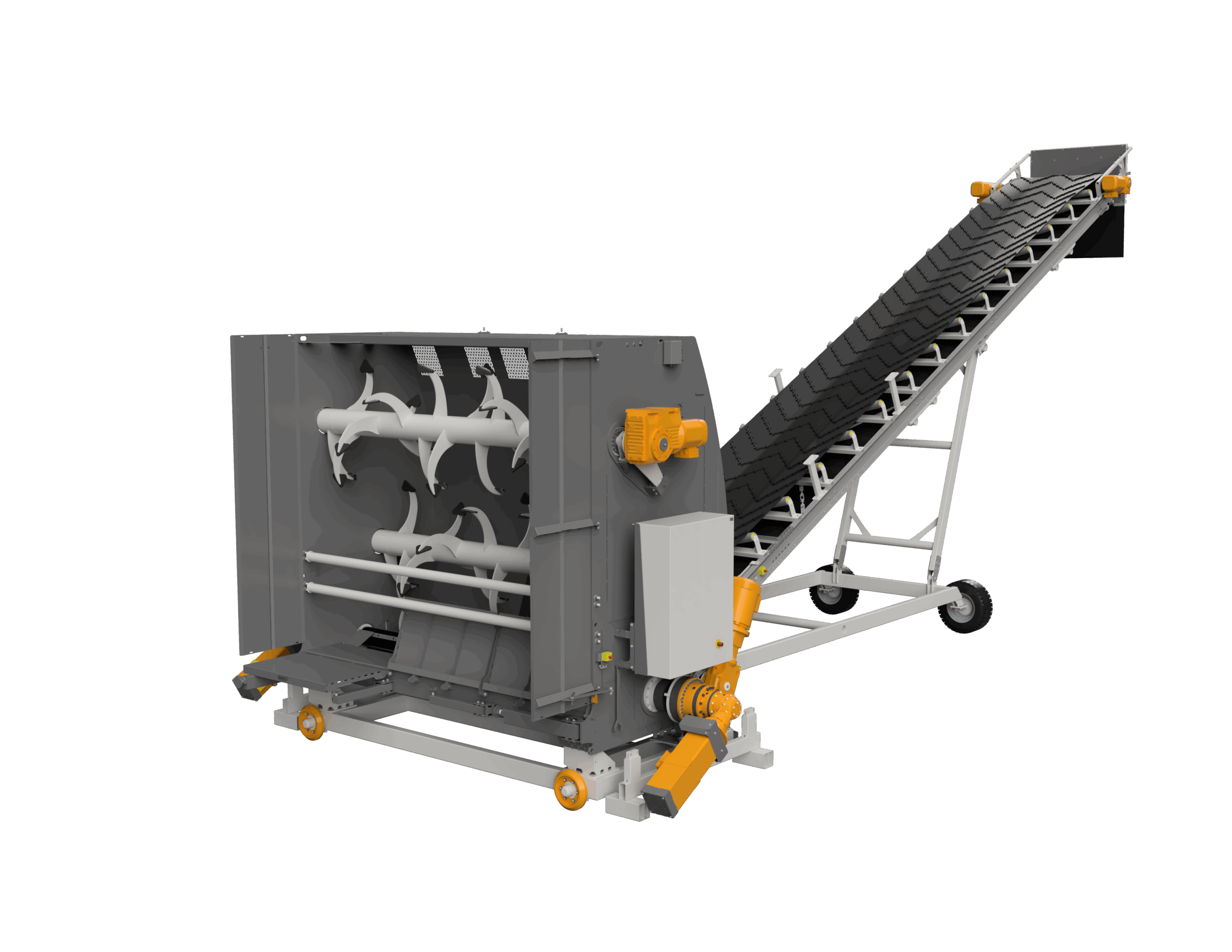

The GTL tunnel emptying winch is designed to quickly, efficiently, and fully automatically remove compost from composting tunnels. Using a pulling net, the compost is extracted from the tunnel, loosened by powerful rotating spades, and conveyed via a screw to the discharge conveyor. This conveyor then transports the compost to the next machine, such as the GTL cascade conveyor.

Thanks to its robust stainless steel construction and precisely PLC-controlled winch mechanism, the tunnel emptying winch ensures reliable operation, even in tunnels up to 44 meters long. The system reduces labor intensity, speeds up the process, and integrates seamlessly into modern composting facilities.

FAQ

What does a tunnel emptying winch do?

It automatically removes compost from composting tunnels, loosens it, and transports it to a conveyor.

How does the machine work?

A pulling net extracts the compost from the tunnel. While the net is rolled up, rotating spades loosen the compost, which is then conveyed via a screw to the discharge conveyor.

What tunnel sizes are suitable?

The GTL tunnel emptying winch can handle tunnels up to 44 × 4 × 4.5 meters.

Where does the compost go?

It is transported via the discharge conveyor to the next machine, such as a cascade conveyor.

What are the main benefits?

Less manual labor, faster tunnel emptying, consistent output, and durable construction.

Can the winch be moved?

Yes, the machine is equipped with a drive system to move sideways along the tunnel.

Can GTL adapt the machine to my company’s needs?

Yes, every machine is customized to meet the client’s specific requirements and conditions.

What service and support does GTL provide?

We provide installation, training, after-sales, and worldwide service.